IDEX Technology–Independent Dual Extruder 3D printer

Опубликовано menglisa

Some customers come to ask us “what are the benefits of IDEX 3D Printing” from time to time. “do dual extruders print faster”? or ” Are dual extruders 3D printers worth it?” Today, we are going to dive into this topic and answer these frequently asked questions. We sincerely hope that this article can help you to gain a clear picture of the IDEX 3d printer.

What is an independent dual extruder or Independent Dual Extrusion (IDEX) 3D printer?

IDEX is the abbreviation of “independent double extruder” (someone may call it “Independent Dual Extrusion” as well), which refers to the printing technology that allows the 3D printer and its two extruders to work independently at the same time. There are two independent extruders/two printheads side by side on the IDEX 3D printer and two filament spools. The IDEX printer can use the filaments from the two spools at the same time or alternately. By using the 3D printer with two independent extruders, you can print two identical models at once (at the same time), thus significantly improving production efficiency.

Independent dual extruder printers have duplication printing mode and mirror printing mode to double their printing efficiency. It is the best choice for enterprises and universities to quickly obtain small batches of high-quality, high-precision, and multi-functional prototypes in production and research.

Users can freely combine two different materials and two different filament colors according to their actual needs. For example, they can use two filaments of the same material with different colors, or they can use filaments of different materials and colors. Different colors or types of filament with various effects can enrich the color and texture of 3D printed products.

Suppose you choose a 3D printer of an independent dual extruder (IDEX) system. In that case, two extruders/nozzles can print two products simultaneously, or two nozzles can work together (two nozzles use different materials) to print the same product. You can print more finished products at the same given time. IDEX technology, which usually appears on professional industrial printers, has recently begun to be popular in the home DIY 3D printer.

Why do independent dual extruder printers attract so much attention from professional consumers in recent years? What are the advantages of IDEX 3D printer?

1. Duplication printing (printing two identical models simultaneously)

Duplication mode means that the two print models’ size, angle, and direction are exactly the same.

Independent dual extruder 3D printer, its two extruders and nozzles can operate and print independently simultaneously, and two models/products can be printed on one 3D printer simultaneously. For example, you may need an hour if you use a single extruder 3D printer to print a vase. But if you use an independent dual extruder printer, you can print two vases simultaneously, so it only takes you about an hour to print two vases. In the same given time, the output/production is increased and doubled. It is very suitable for enterprises to produce batch models/products.

2. Mirror Printing

What is mirror mode? Mirror mode refers to the printing mode in which a printer with an independent double extruder print two symmetrical models at a time in the 3D printing process. The two models printed in mirror mode are mirror-symmetrical, just as we see things in the mirror.

In general, printers equipped with IDEX allow you to print two products at the same time in both copy mode and mirror print mode, significantly increasing the speed of printing. Generally speaking, 3D printers with dual extruder functions are more expensive than single extruder printers.

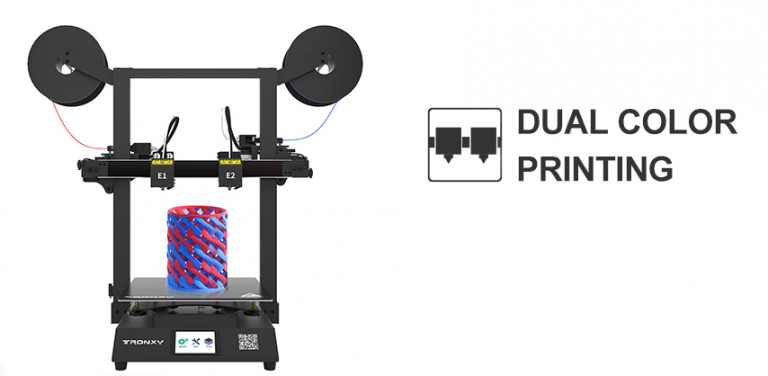

3. Two-color printing, the printing color effect of the model is better

In addition to improving printing efficiency, the dual-color model of independent dual-extruder printers is better than single-extruder 3D printers.

In our IDEX 3D printer GEMINI S, we have nozzle scrapers on both sides of the nozzles to clean the nozzles after printing or before the nozzle prints again. This can prevent filament leakage from the nozzle and blur color and unclear/mixed color on the printed products.

4. You can use water-soluble consumables to print support (with PVA/HIPS consumables).

When the model has many suspended and hollowed-out structures, the suspended parts need to be supported before they can be printed.

In a single-extruder FDM printer, support material and printing material are the same material. To remove the support, you need to remove it manually with knives, pliers, etc. This process is troublesome and dangerous, and the model may suffer some damage. Independent Dual extruder printer does not have these problems. In the IDEX independent dual-extruder, you can print the support parts with water-soluble PVA consumables, eliminating the user’s trouble removing the support.

The printer with an independent dual extruder can load one extruder/nozzle with PVA water-soluble support material to print the support parts. The other extruder can print the main body of the model, and both extruder/nozzles are involved in printing. After printing, we only need to soak the model in water, and the supporting material will dissolve in the water. We can get the ideal finished product without complicated post-processing. This feature enables us to print complex models. The printer with an independent dual extruder can print the model of PVA water-soluble support, which is very conducive to the replication of printing structure, which can help enterprises and scientific research institutions quickly design and prove and verify the rationality of the design. It can significantly improve the timeliness of the design to the finished product.

For example, you can use PLA or ABS filament to print the main body of the model, and use water-soluble consumables like PAV to print supports. After printing, we can obtain a smooth surface model by removing the soluble parts in water. This process does not require complex post-processing to get the finished product.

There are single-extruder 3D printers and dual-extruder 3D printers on the market. How should we choose a 3D printer? Is it better to choose a printer with a single extruder or with a double extruder? The following answers may help you:

1. The parameter setting of the single extruder printer is relatively simple. It is more is easy to operate and is suitable for entry-level users.

While the parameter setting of the dual extruder printer is complicated, the printing may fail due to the improper setting of a parameter. It is difficult for new users to master the parameter settings of the independent dual-extruder. If you have a very comprehensive knowledge of 3D printers, good at designing models, and have high printing requirements, you can consider buying an independent dual extruder printer.

2. The dual extruder 3D printer is very suitable for soluble printing support.

If you are very familiar with 3D printers and need to print some complex models with a lot of arc bevel or hollowed-out decoration, you can choose a dual extruder 3D printer. You can use one extruder/nozzle to print the model, the other extruder/nozzle print soluble support. After printing, you can remove the soluble material by putting the model into the water. The double extruder printer is an excellent choice to print a complicated model with soluble material.

3. Two-color printing, the printed model/product is more beautiful. If you are not satisfied with printing a single-color product and want to get a product with two colors. Then you can use an IDEX 3D printer with dual extruders.

A single extruder 3D printer and an independent dual extruder 3D printer, which one is your favorite? Welcome to share your idea with us and leave comments.

← Предыдущее сообщение Более поздняя публикация →

0 комментарии